| CARBON FILM RESISTORS - FLAME-PROOF TYPE FCR Series | | | | |

| | | | | | | | | | | |

| TYPE | POWER | | FEATURES | | |  |

| FCR-25 | 1/4W | | Lower cost and prompt deliver. | | |

| FCR-50 | 1/2W | | High power-to size ratio for significant space savings. | | |

| FCR-100 | 1W | | Complete flameproof construction-UL | | |

| FCR-200 | 2W | | Excellent long-term stability. | | |

| FCR-300 | 3W | | Wide resistance range : 1Ω ~ 10mΩ | | |

| | | Standard tolerance : ±5% | | | | |

| | | | | | | | | | | |

| INTRODUCTION | | | | | | | | | |

| | | | | | | | | | | |

| The FCR series flame-proof Carbon Film Resistors are manufactured by Coating a homogeneous film of pure carbon on high grade ceramic rods, resistance less than 10 have an electroless deposited nickel film, and are coated with layers of gray color flame-proof lacquer. These resistors meet overload tests in accordance with UL specification without producing a fire hazard. |

|

| | | | | | | | | | | |

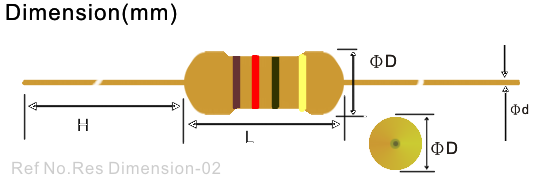

| DIMENSIONS: | | | | | | | | | | |

| | | | | | | | | | | |

| STYLE | DIMENSION (mm) | POWER RATING | |  |

| L | ΦD | H | Φd | (Watt) | |

| FCR-25 | 6.3±0.5 | 2.3±0.3 | 28±2 | 0.6±0.05 | 1/4W | |

| FCR-50 | 9.0±0.5 | 3.2±0.3 | 26±2 | 0.6±0.05 | 1/2W | |

| FCR-100 | 11.5±1.0 | 3.2±0.5 | 35±2 | 0.8±0.05 | 1W | |

| FCR-200 | 15.5±1.0 | 4.5±0.5 | 32±2 | 0.8±0.05 | 2W | |

| FCR-300 | 17.5±1.0 | 6.5±0.5 | 35±2 | 0.8±0.05 | 3W | |

| | | | | | | | | | | |

| ELECTRICAL CHARACTERISTICS: | | | | | | | |

| | | | | | | | | | | |

| Style | FCR-25 | FCR-50 | FCR-100 | FCR-200 | FCR-300 | | |

| Power Rating 70oC | 1/4W | 1/2W | 1W | 2W | 3W | | |

| Operating Temp. Range | -55oC ~ +155oC | | |

| Max. Working Voltage | 250V | 350V | 500V | 500V | 600V | | |

| Max. Overload Voltage | 500V | 700V | 1000V | 1000V | 1000V | | |

| Dielectric Withstanding Voltage (AC) | 500V | 700V | 1500V | 1500V | 1500V | | |

| Max. Intermittence Overload Voltage | 750V | 1000V | 1500V | 2000V | 2000V | | |

| T.C.R.(ppm/℃) | FCR-25 /FCR-50 | FCR-100 /FCR-200 /FCR-300 | | |

| 100KΩ down | 100K~1MΩ | 1MΩ up | 100KΩ down | 100K~1MΩ | 1MΩ up | | |

| -0.7 | -0.5 | -0.35 | +350PPM | -0.7 | -0.35 | | |

| * The listed resistance range for standard resistance, below or over this resistance is on request. | | |

| | | | | | | | | | | |

| ENVIRONMENTAL CHARACTERISTICS : | | | | | | |

| | | | | | | | | | | |

| PERFORMANCE TEST | TEST METHOD | APPRAISE |

| Short Time Overload | JIS-C-5202 5.5 : 2.5 times RCWV for 5 seconds | ±(0.75%+0.05)Ω |

| Dielectric Withstanding V. | JIS-C-5202 5.7 : in V-Block for 60 seconds | By Type |

| Temperature Coefficient | JIS-C-5202 5.2 : -55oC ~+155oC | By Type |

| Insulation Resistance | JIS-C-5202 5.6 : in V-Block | ≧1000 MΩ |

| Solderability | JIS-C-5202 6.5 : 230oC for 5±0.5 seconds | 95% min. coverage |

| Resistance to Solvent | JIS-C-5202 6.9 : Trichroethance for 1 min. with ultrasonic | no deterioration |

| Terminal Strength | Direct load for 10 sec. In the direction of the terminal leads | ≧2.5KG/24.5N |

| Pulse Overload | JIS-C-5202 5.8 : 4 time RCWV 10000 cycles(1 sec.on, 25 sec.off) | ±(2%+0.05)Ω |

| Load Life in Humidity | JIS-C-5202 7.9 : 40±2oC, 90~95% RH at RCWV for 1000 hrs | ±(3%+0.05)Ω |

| (1.5hrs. on, 0.5 hrs. off) |

| Load Life | JIS-C-5202 7.10 : 70oC at RCWV for 1000hrs (1.5hrs.on, 0.5hrs.off) | ±(3%+0.05)Ω |

| Temperature Cycling | | ±(1%+0.05)Ω |

| Soldering Heat | | ±(1%+0.05)Ω |

| | | | | | | | | | | |

|

|

|

| | | | | | | | | | | |

|